Renewable energy

We want to show some of the seeds we are currently sowing for future years, which will be more fully developed over the following decades, whereas we are continuing to foster our talent and adapt our assets to energy transition and the growing need for renewable energy.

Our objective is to create a constant flow of ideas to generate new solutions and be ready to take a bet on the ideas we believe in. Being part of an international group like Saipem adds an element of diversity and provides access to a vast selection of multiple skills, which is an enormous advantage for putting an idea into practice.

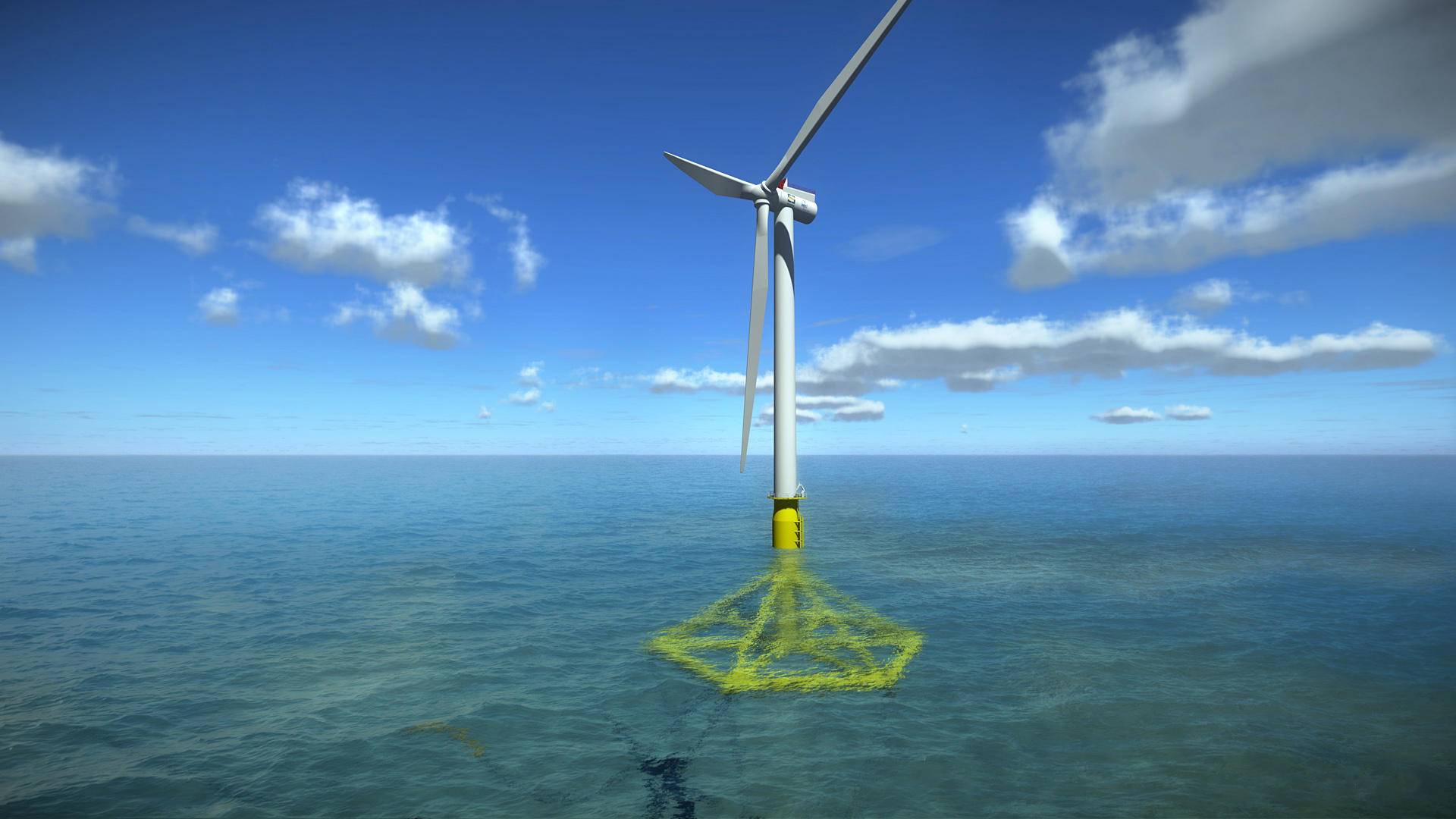

Wind energy, Star1 and HexaFloat™

We have the expertise to develop every stage of wind energy projects, from the initial assessment and engagement phase to the final delivery.

We are advancing the development of two concepts, the STAR1 semi-sub and the Hexafloat™, pendulum design, to provide the most tailored solution to the market.

One example is the development of the concept of the floating, pendulum foundation, HexaFloat™, for wind turbines at sea.

This enables floating wind turbines to be installed in sea areas where the wind is usually stronger, but the sea is too deep for a traditional, fixed foundation.

This solution consists of a floating part, stabilised by a counterweight connected to the floating part by rods.

The HexaFloat™ substructure aims to be a single foundation for different sized turbines, thanks to a counterweight that can be lowered to stabilise heavier loads.

In order to fit the different turbine sizes, the tubular structure diameter can be adapted and the depth of the ballast can be regulated. The structure is fastened to the seabed via mooring cables and anchors.

The export cables will be attached in a "lazy wave" configuration to reduce the need to prepare the seabed to the minimum.

In 2021, we also added the STAR1 semi-submersible technology to our floating offshore wind technology portfolio. This is a centred-turbine floater with 3 external columns connected to the central one by submerged pontoon. In 2022, we refined the STAR1 design for large-scale commercial turbines. Early 2023, Saipem has completed the design and structural optimization of STAR1 for large-scale future commercial turbines of 15 MW with the aim to reduce structures weight and fabrication costs to improve competitiveness of floating wind vs. bottom-fixed offshore wind. Innovative connections between columns and structural arrangements have also been investigated and validated for harsh sea conditions.

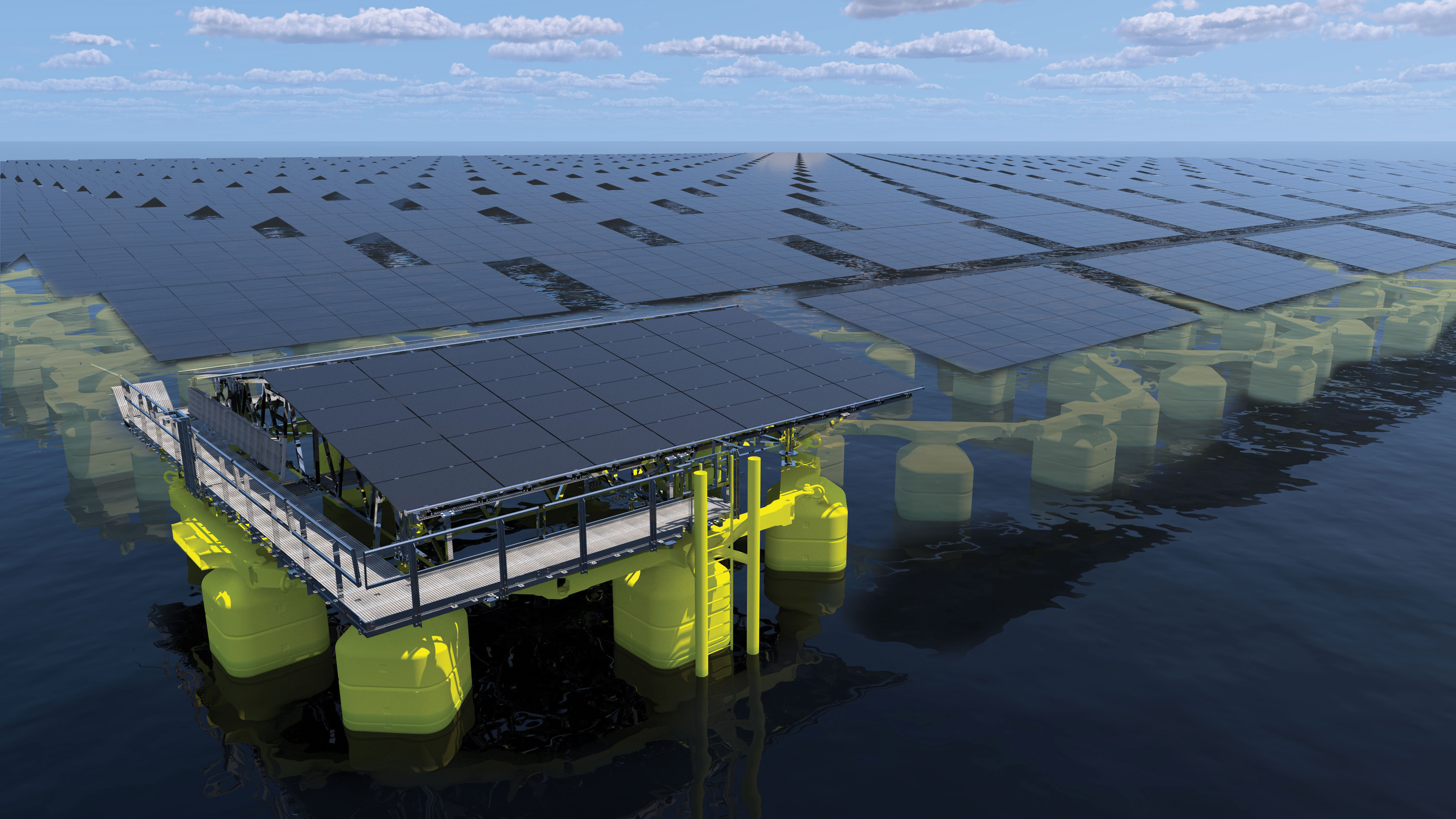

Solar energy and renewable energy projects

Photovoltaic solar energy (PV) is the most cost-effective source of renewable energy that is abundantly available throughout the world and can be easily implemented.

We carry out complex projects that fully integrate traditional technologies with photovoltaic installations to contribute to the decarbonisation of the production sector.

By exploiting the expertise of our Norwegian company, Moss Maritime, we have the skills to develop floating photovoltaic installations near-shore and offshore. Our patented solution enables:

- a modular design that facilitates construction and repair

- customisation to adapt to various sites and requests for power

- operations in waves without damaging the solar panels

The CO2 value chain

Carbon capture, use and storage (CCUS) can make a significant impact on reducing emissions in the “hard-to-abate” sector, whereas biofuel production processes and technologies based on biomasses can provide a key alternative to traditional fossil fuels for heavy and long distance transport (e.g. by sea or air).

Saipem can handle the entire CO2 capture, use and storage chain, thanks to its solid background in long-distance pipeline fluid transportation and offshore drilling for CO2 reinjection.

In April 2023, Saipem and Mitsubishi Heavy Industries (“MHI”) have signed an agreement that allows Saipem to use MHI's proven technologies for post-combustion CO2 capture in the implementation of large-scale projects.

More in general, we have completed EPC projects involving not only the removal of CO2 and the reinjection of acid gases, but also CO2 pipelines.

Additionally, we have developed our own proprietary technology "CO2 Solutions by Saipem" based on an innovative, enzymatic process to capture CO2.

The technology was tested in a small capacity commercial plant operating at the pulp mill, Resolute Forest Products, in St. Félicien (Quebec, Canada).

The recovered CO2 is purified and used in the greenhouses of a local farm. Enzymatic CO2 capture is more environmentally sustainable compared to traditional CO2 capture processes.

Lastly, we are paying special attention to decarbonising the hard-to-abate industries that are considered to be some of the most complex, as the carbon dioxide they emit is not only due to generating heat and power, but actually to their manufacturing process.

As a result, innovative solutions are required. for which Saipem is already collaborating with various industrial and technological leaders on the sustainable reconversion of high energy-consuming installations in the primary industry in the metallurgical sector, especially in the steel production process.

The objective is to create a new, sustainable model, compliant with the new legislation on environmental protection.

The "ACCSESS" inovation project

A further, major step towards achieving our objectives to reduce CO2 emissions in Europe is the innovation project "ACCSESS"

Funded in 2021 by the Horizon2020

The aim of the initiative is to develop an integrated chain to capture and store CO2, which interconnects active initiatives and existing infrastructures or those under construction in European continental zones and in northern Europe.

Lastly, the ACCSESS project will develop practical, sustainable business models for the industry to capture, store and use CO2, which will focus on citizens and European cities to encourage a new culture based on circulating end products and services with a zero, or at least positive climate impact.

One of ACCSESS objectives is to obtain certification for Saipem CO2 Solutions technology to capture CO2 from flue-gas from industries with a complex carbon footprint, e.g. paper, cement and waste treatment, by using a modular, transportable, small-scale (2 tpd) solution.

In 2022, a 2-ton-per-day pilot plant, previously designed to be operated with amine solvent, was modified to operate with our CO2 Solutions technology. The pilot plant has been successfully operated with our technology in the waste-to-energy plant Hafslund Oslo Celsio in Klemetsrud, marking the first important milestone of ACCSESS. After the completion of testing in Klemetsrud, the pilot has been moved to the Technology Centre Mongstad to be integrated with a Rotating Packed Bed absorber unit developed by Prospin and constructed by Proceler. Preliminary runs have demonstrated stable operations well satisfying target performance. This represents the next stage of development of our CO2 Solutions technology, with the goal of providing the market with a modular, fast and easy-to-build product. From end 2023 to 2024, we will conduct CO2 capture test campaigns at the Stora Enso kraft pulp mill in Skutskär, Sweden, and at the Heidelberg Cement kiln in Górażdże, Poland.

Conversation of biomasses and circular economy

We have studied the bio-fuel production processes and technologies in detail, with a special focus on second generation bio-ethanol.

This was the framework for the agreement we signed with Versalis to promote the PROESA® technology used to produce sustainable bio-ethanol and chemical substances from lignocellulosic biomass.

The PROESA® process does not use food crops for human consumption as its raw material. Instead, it produces second generation bio-ethanol via a process of hydrolysis and the subsequent fermentation of agricultural biomasses in plentiful supply (e.g. agricultural waste, wood shavings and energy crops).

As far as the circular economy is concerned, we recently signed an agreement with Quantafuel ASA to collaborate in the industrialisation and construction of chemical recycling plants for waste plastics using Quantafuel’s technology. This allows us to market and construct industrial plants specialised in pyrolysis, which turns solid plastic waste into liquid or gaseous products that can be reused as fuel or chemical raw materials for plastic recycling.

Hydrogen

Hydrogen has drawn the attention of public opinion as the possible "shining star" that will free the world from fossil fuels and the carbon economy.

The decarbonisation of hydrogen production is necessary if this energy source is to remain active and act as energy carrier and chemical reactant in energy transition.

Saipem is considering blue hydrogen (hydrogen from fossil fuels with carbon capture) and green hydrogen (hydrogen from water electrolysis with renewable energy).

Whereas green hydrogen is the end objective, blue hydrogen is a compatible opportunity to offer a market solution more rapidly over the next two decades. The conceptual design of blue ammonia facility has been completed as part of the Barents Blue Ammonia Project pre-FEED activities.

Puglia green hydrogen valley

In 2021, Saipem, Edison, Snam and Alboran Hydrogen signed a memorandum of understanding (MoU) to jointly develop the Apulia Green Hydrogen Valley project, one of the first initiatives in Italy to produce and transport green hydrogen on a large scale.

The project aims to accelerate the use of green hydrogen by helping both Italy and the European Union to achieve their objectives of climate neutrality by 2050.

The Apulia Green Hydrogen Valley project envisages the construction of three plants to produce green hydrogen in Brindisi, Taranto and Cerignola (Foggia), with a total capacity of 220 MW, powered by a 380 MW photovoltaic installation.

Once fully operational, we estimate the three plants will be able to produce a total of up to approximately 300 million cubic metres of renewable hydrogen/year.