The project

Woodside Energy, a global energy company founded in Australia, is developing the Scarborough natural gas field, located in the Carnarvon Basin, approximately 375 km off the coast of Western Australia. For this project, called the “Scarborough Energy Project,” Saipem installed a trunkline to connect a semi-submersible floating production unit (FPU), anchored at a depth of 950 metres, to a second LNG train (Pluto Train 2) at the onshore Pluto LNG plant.

Initially, eight wells will be drilled, with a total of 13 planned over the life of the field. The project is set to produce up to 8 million tonnes per year (Mtpa) of LNG, with about 5 Mtpa processed through Pluto Train 2 and up to 3 Mtpa through Pluto Train 1.

An Extraordinary Project

The construction of the trunkline, with a variable diameter of 32”/36” and a length of 433 km, was carried out using the Derrick Lay Barge Saipem Endeavour for the near-shore section in shallow water, and the flagship vessel Castorone for the remaining section of over 400 km, in waters up to 1,400 metres deep.

Among the most advanced technologies on board the Castorone are state-of-the-art welding systems, developed by Saipem Welding System, a proprietary solution that integrates hardware and software for automating the welding process. These systems work in synergy with qualified NDT (Non-Destructive Test) tools, dedicated to non-destructive testing and joint coating.

Pipe handling on the Castorone is automated with high-level safety systems to prevent accidents related to moving pipes. For the Scarborough project, Saipem used for the first time a prototype, designed and built together with project partners, that allowed the hands-free transfer of pipes from support vessels to the Castorone, minimising human intervention near the pipes during lifting and reducing associated risks. This system will be further implemented in future applications.

Saipem also used for the first time on the Castorone the innovative proprietary Integrated Acoustic Unit (IAU) technology, a digital tool based on acoustic monitoring and therefore non-intrusive, which allows real-time examination of the integrity of offshore pipelines during laying activities.

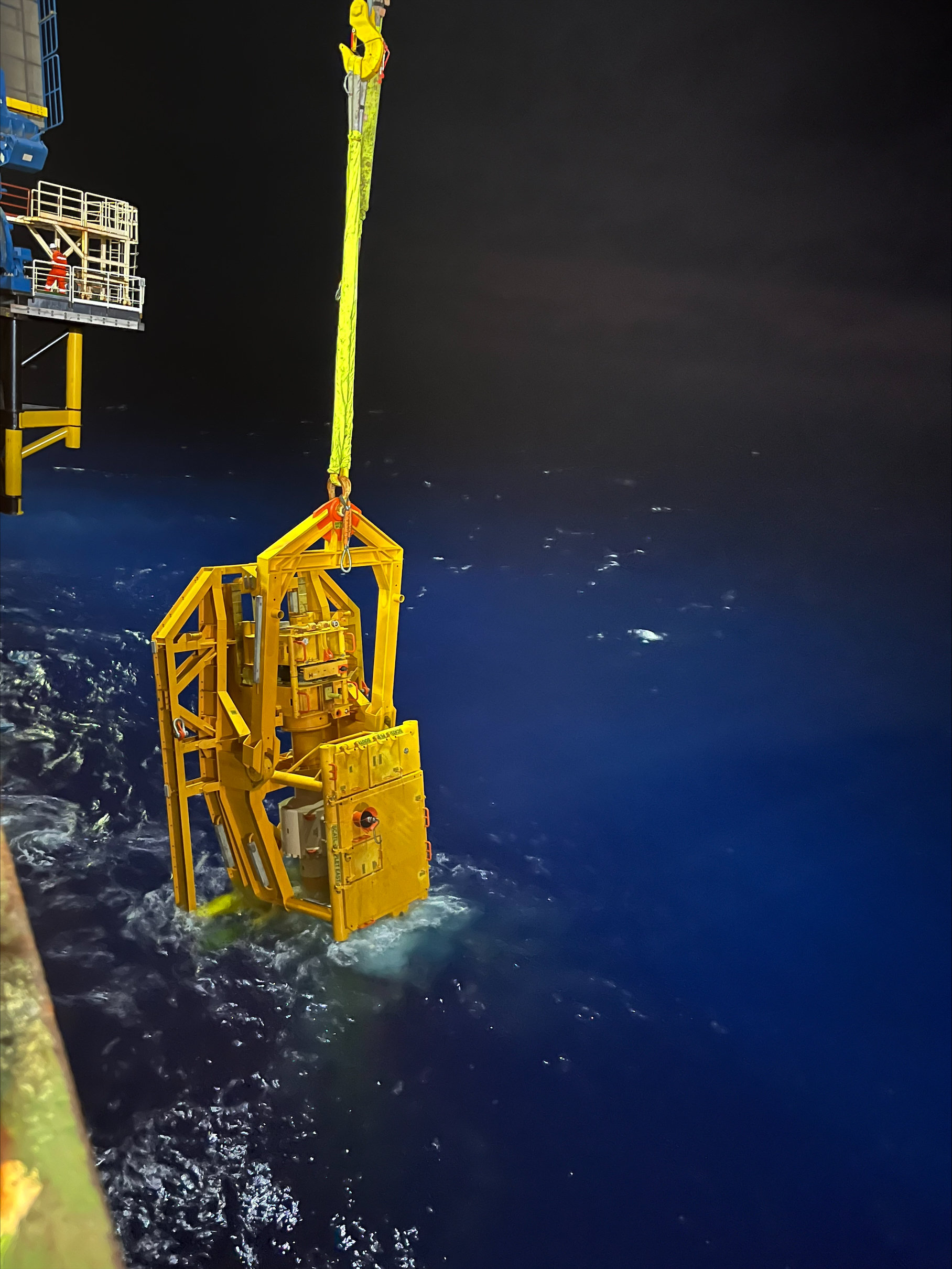

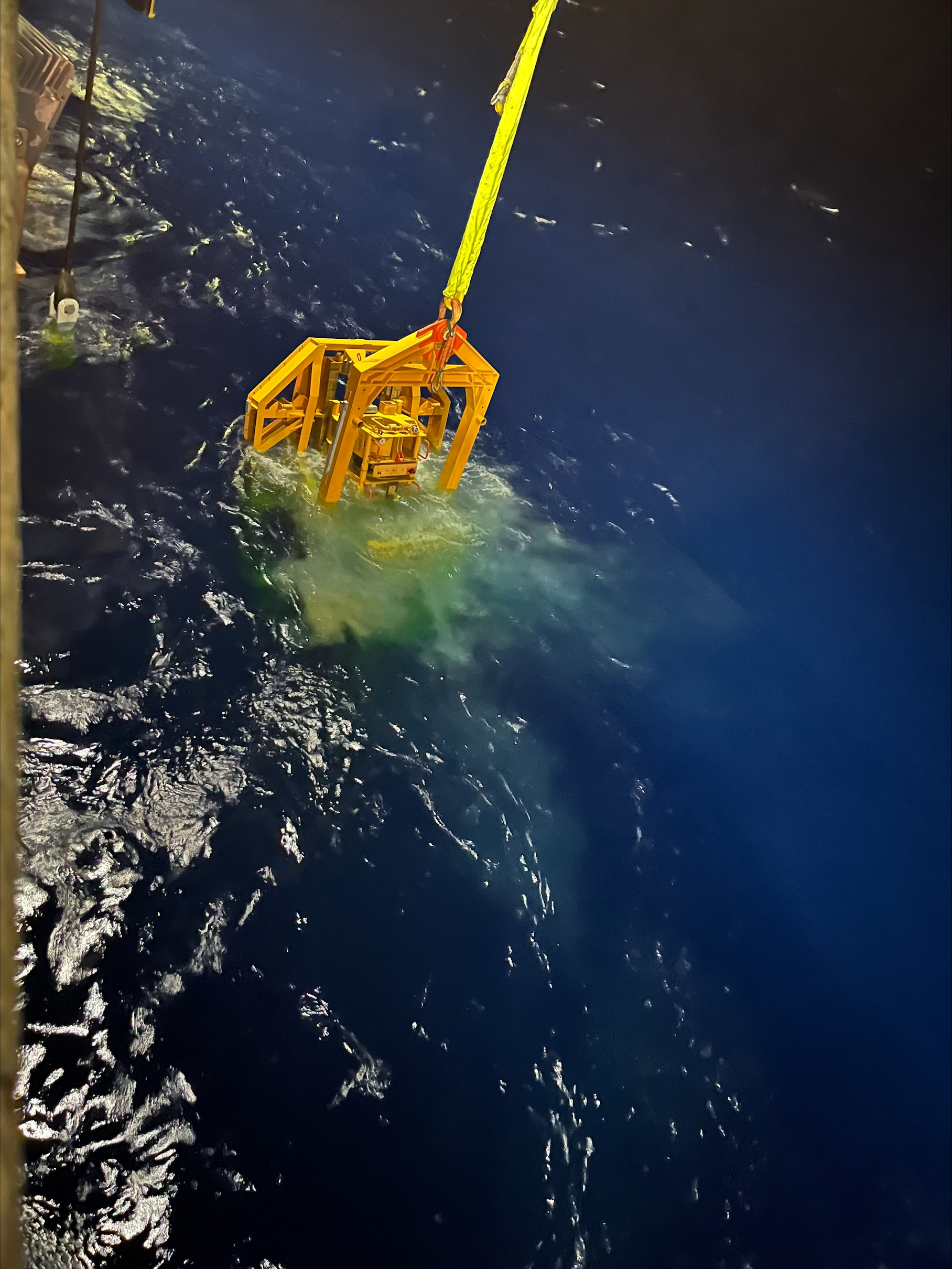

In addition, the construction of the Scarborough trunkline was supported by two Working Class Remote Operating Vehicles (ROVs) Innovators operating 24/7 in deep water. The ROVs are part of the fleet developed by Sonsub, Saipem’s centre of excellence for underwater robotics and technology.

The digitalisation of the Scarborough project consists of an innovative solution for the collection and management of key data during the various phases of line fabrication and launching (desk-to-seabed approach). This solution promotes quality control and efficiency of key production processes and effective integrity monitoring during the execution phase, thus enabling dry pre-commissioning of the line, compared to traditional pre-commissioning systems that use water and inhibitors. The resulting database can be considered a digital twin of the pipeline, ready to be transferred to the operation and maintenance phase. The data was organised according to standards that optimise interfaces both with contractors and the client. Real-time installation data gathered from multiple automation systems on both the Castorone and Saipem Endeavour was crucial, requiring continuous monitoring to ensure optimal data quality and reliability.

For this project, a technological innovation called PLET Support Structure (PSS) was also implemented to overcome some critical issues related to the installation of the Pipeline End Termination, due to its considerable size, water depth, and remote, challenging operational area. The new system increases efficiency and operational control, achieves advanced quality management, and improves safety during installation.

Finally, the Scarborough project applied, for the first time in offshore operations in Australia, the requirements of Dry Commissioning, a new standard that eliminates cleaning and hydraulic testing and ensures more responsible and efficient use of water. Its application represents a technological milestone and a high level of attention to environmental impact.