Saipem’s History

A journey spanning over 65 years of innovation, engineering excellence and global leadership in the energy sector.

1957 - 1969

Engineering for a sustainable future, how it all began

Economic expansion. A new European Union. Cold War tensions beyond the Iron Curtain and the rise of technology set to change the course of history. As Italy experienced an economic and demographic boom, and the world underwent profound transformations in the aftermath of the Second World War, Saipem was founded.

1957 The origins of Saipem

Saipem was established as an independent company through the merger of SAIP and Snam Montaggi (Società Azionaria Italiana Perforazioni E Montaggi), with the aim of creating a new Italian engineering entity. Initially operating as a service provider for Eni, it contributed to the post-war economic boom, in an Italy transitioning from an agricultural country to an industrial power.

Its foundation took place during a period of intense innovation, between the Space Age and the birth of the European Community, and reflected the vision of Enrico Mattei, who saw Saipem as a natural step in the expansion of the Eni Group.

the strength of an idea

Mattei's vision, the strength of an idea

Enrico Mattei was the visionary mind behind the creation of Saipem. Founder of Eni and advocate of an open and innovative industrial model, he immediately understood that Italy needed a company capable of competing globally in technological and infrastructural terms. He saw Saipem as the engineering and operational arm of the Eni Group: an organisation able to take Italian know-how beyond national borders, build alliances and support the economic development of emerging countries. His vision, rooted in integration, research and energy autonomy, laid the foundations of the corporate culture that still defines Saipem today.

«The need to create integrated industrial groups has become increasingly evident with the growing importance of the oil industry,» Mattei stated when referring to the post-war period. «This could not go unnoticed even in our country, which is not isolated but part of a world where industry is reaching the highest levels of integration and complexity.»

1958–1963

Early offshore challenges and urea engineering

In just a few years, Saipem built its technological know-how, marking key milestones in industrial engineering.

Innovation, experimentation and openness to global markets became the pillars of its growth.

1964–1966

Research, industry and a technological fleet

During these years, Saipem turned research into industrial enterprise: the San Donato Milanese laboratory evolved into a centre of excellence for urea technology, and the first semi-industrial plants were developed in Sicily and Spain. At the same time, the company expanded its offshore infrastructure, from the conversion of the vessel Castoro 1, the first pipelayer in its fleet, to growth in the refining and chemicals sectors.

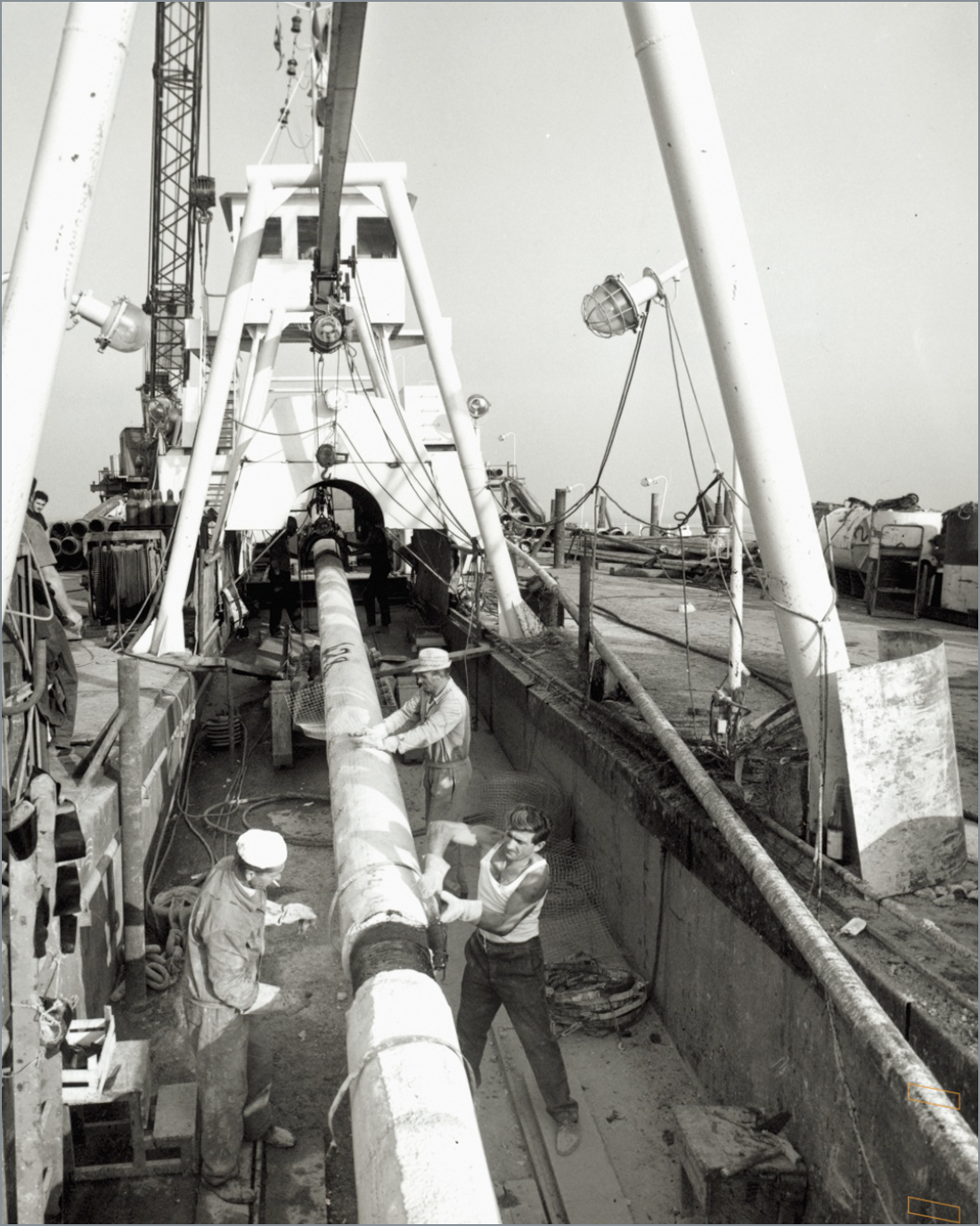

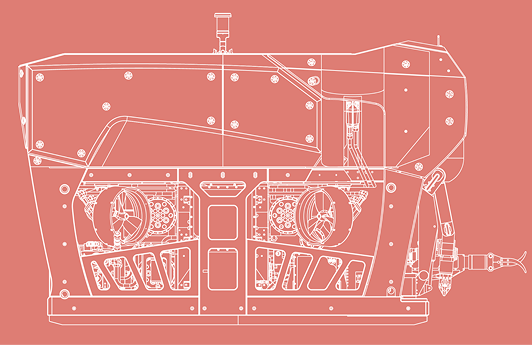

The Firing Line: precision and power in action

The Firing Line of the Castoro Sei vessel consisted of a fixed central ramp for pipe laying, connected to internal and external ramps designed to adjust the laying angle at different depths. In deep waters or challenging conditions, it could be further extended. Along the ramps were three 110-tonne tensioning stations, nine workstations (welding, X-ray inspection and joint coating), and multiple support rollers.

1967–1969 Consolidation and international recognition

The end of the decade marked Saipem’s technological maturity. With the drilling of over 700 wells in Argentina and the installation of platforms in the Adriatic Sea, the company earned a global reputation. As the world entered the space and digital age, Saipem proved its ability to tackle the most complex challenges, from seabed operations to global energy needs, consolidating its role as a pioneer of international engineering.

Insights

Fertilisers:

Snamprogetti™ Urea Tecnology

Fertilisers: Snamprogetti™ Urea Technology

The first patent for urea technology was registered by Snamprogetti™, later incorporated into Saipem, in March 1962.

The following year, Snamprogetti™ installed the first pilot plant at the Eni Group laboratories in San Donato Milanese, where research into the total recycle stripping process was developed, destined to become a benchmark technology.

1972 – Integrated ammonia–urea plant

Snamprogetti studied the integration of ammonia and urea plants into a single system, in which all the ammonia produced was converted into urea.

1975 – Innovative adoption of the carbamate ejector

The introduction of the carbamate ejector made it possible to design plants with a horizontal layout, significantly reducing costs and simplifying maintenance.

1976 – Low-biuret urea production process

A process was developed to produce urea with low biuret content, improving fertiliser quality and reducing waste.

1982 – High-efficiency urea production process

Increased production efficiency led to reduced steam consumption, representing a major step forward in lowering operating costs.

1984 – Innovation in piping materials

The use of bimetallic pipes (zirconium and stainless steel) in the stripping system improved resistance in critical environments, increasing the reliability of the plant’s most sensitive equipment.

1989 – Purification of urea plant effluents

The adoption of deep hydrolysis enabled the complete purification of process condensates and their reuse as boiler feedwater.

1995 – Enhanced urea synthesis process

The new process increased urea yield, further optimising costs and industrial performance.

Onshore patents:

innovations generating progress beyond the energy sector

Onshore patents: innovations generating progress beyond the energy sector

Over the years, Saipem has developed numerous other onshore patents across a wide range of fields, demonstrating how the company’s activities have often generated positive spillover effects in other industrial sectors as well. Notable examples include improvements in air quality related to road traffic and the enzymatic splitting of lactose in milk into glucose and galactose.

1967

The opacimeter is an instrument used to measure the opacity of exhaust gases, generally employed in the automotive sector to assess pollutant emissions from diesel engines and support the development of new engines.

Thanks to this device, it was possible to carry out the first measurements of exhaust gas emissions from external combustion engines, making a significant contribution to early tests aimed at improving air quality related to road traffic.

1970

A process was developed for the enzymatic splitting of lactose in milk into glucose and galactose, laying the foundations for the subsequent introduction of HD milk by the Milan Central Dairy.

Coal-Water Fuel (CWF) technology attracted considerable attention, particularly after the oil crisis of the 1970s. Towards the end of the decade, Snamprogetti developed its proprietary REOCARB™ technology, dedicated to the production, transport and combustion of Coal-Water Fuel.

1986–1989

Snamprogetti designed and built in Siberia the first integrated plant for the transport and combustion of CWF, located in the Belovo district near the coal mines. The facility included a production plant with a capacity of 3 million tonnes per year of slurry and dry coal, and a 262 km pipeline to transport the fuel to the Novosibirsk power plant.

1992

A mobile modular plant for the production and development of biotechnological products at pilot scale was developed (Pharmadule).

An innovative concept that introduced the modularisation of biotechnological pharmaceutical plants, paving the way for a new approach to designing and building flexible production facilities that are easily transportable and adaptable to different research and production needs.

1970 - 1985

Exploring new frontiers

As Saipem expanded into new regions of the world, its challenges grew alongside increasing geopolitical instability. The company’s flexibility and its ability to interpret change have consistently enabled it to deliver the most effective solutions, supporting its successful growth and recognition on a global scale.

1971-1972

First global challenges

In the early 1970s, Saipem faced its first true global challenges. The oil crisis in the Middle East pushed the company to seek new energy sources, opening operations in the North Sea. In this context, flexibility became a defining characteristic of Saipem and a driver of continuous evolution. The company expanded its portfolio with cutting-edge processes, ranging from liquefied natural gas developed by Moss Maritime to Snamprogetti solutions for the enzymatic splitting of lactose.

1974 New offshore achievements

This was the year Saipem consolidated its offshore leadership. After setting a record with the laying of a pipeline at a depth of 130 metres off the coast of Gaeta, the company took on more complex seabeds and introduced new laying methods and devices. This journey culminated in 1974 with the construction of the pipeline across the Strait of Messina, one of the most significant engineering achievements of the decade.

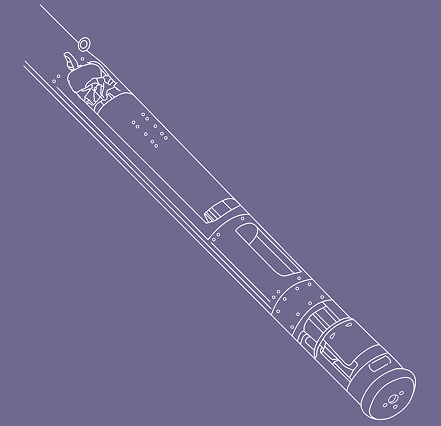

trenching offshore

Behind the scenes of offshore trenching

Trenchers belong to a category of construction machinery used for the essential task of excavating trenches for pipelines or cables, for drainage systems and even for military purposes. The term covers a wide range of specialised equipment: from trenching machines small enough to be operated by a single person, to units mounted on tractors and skid loaders, up to much larger heavy-duty models.

Among Saipem’s solutions in this field is Beluga, a deepwater trencher capable of excavating pipeline trenches with gradients of up to 40 degrees and at depths exceeding 2,000 metres below sea level. The actual excavation is carried out using two cutting discs operating in up-milling mode, capable of working in challenging soils such as ultra-dense clay with a strength of 30 MPa, while debris is removed by two retractable impeller pumps.

1978–1984

First international alliances

Between the late 1970s and the early 1980s, Saipem launched its first major global alliances. Expansion into new markets required collaboration with local partners able to navigate very different regulatory, cultural and operational contexts. Joint ventures, thus, became a strategic tool, enabling Saipem to access new regions and combine different perspectives, fostering innovation.

During this period, the company strengthened its international reputation as a reliable and flexible partner, capable of bringing together global know-how and local expertise.

Saipem goes public

In the 1980s, Saipem took another major step forward to strengthen its role as a leader in the energy and infrastructure sector. The pivotal moment came in 1984, when the company was listed on the Milan and Paris stock exchanges. This decision marked a crucial turning point in its evolution: entry into international financial markets confirmed Saipem’s industrial strength and attracted the attention of global investors.

The listing thus became not only a recognition of the value built over the years, but also a catalyst for future projects, opening up new opportunities for growth, innovation and investment on a global scale.

Insights

Pipelaying

Technologies for reliable installation, even in open seas

Pipelaying: technologies for reliable installation, even in open seas

Offshore pipeline installation must contend with predictable yet not always controllable factors. Currents, waves, seabed morphology, depth and temperature can exert significant stress on pipelines during installation, slowing operations or causing damage.

For this reason, research focuses on solutions capable of compensating for sea-induced movements, acting both on the design of pipelay vessels and on firing line equipment.

The goal is to carry out large-diameter operations, at different depths and in any weather and sea conditions, quickly and in complete safety for people and the environment.

Castoro II Tensioner

Pipeline tensioning device

Castoro II was the first Saipem vessel to be equipped with tensioning devices. These systems are used to lay pipelines while maintaining a constant, controlled elongation.

The tensioner consists of a double pressed track that replaced the clamps previously used. It is an effective and flexible solution, capable of adapting to different pipeline diameters.

The system proved able to optimally manage both laying and stopping phases, continuously adapting to changes in the seabed. Thanks to the use of tensioners, operational limits once considered insurmountable became new achievable targets.

Castoro Sei

Semi-submersible pipelay vessel for pipeline installation on the seabed, including deep waters, and related operating method

Castoro Sei was the first semi-submersible vessel in the Saipem fleet and introduced innovative solutions for operating in challenging marine conditions. Offshore pipelaying must deal with currents, waves and seabed variations that can stress pipelines; for this reason, research focused on systems capable of compensating for sea movements and ensuring safe operations at varying depths.

As a semi-submersible vessel, Castoro Sei provides high stability and operability even in rough seas. Among its distinctive features is a nine-degree inclined firing line, enabling installation at greater depths while reducing the impact of vessel movements on the pipeline. The composite ramp and the hydraulically controlled internal and external ramps follow the required curvature in real time, based on data processed by two onboard computers.

Over the years, Castoro Sei has become Saipem’s flagship vessel, reaching new operational depths and setting records in offshore pipelaying.

LNG

The origins of global liquefied natural gas transport

LNG: the origins of global liquefied natural gas transport

Towards the end of the 1950s, an LNG carrier crossed the Atlantic Ocean for the first time with its cargo of liquefied natural gas. This event opened up new market opportunities for this fuel and stimulated research aimed at improving liquefaction and regasification systems.

At the origins of modern LNG

Saipem’s efforts along the LNG liquefaction and regasification chain began in the 1960s, when it built the Marsa El Brega liquefaction plant in Libya for Esso Standard Inc. and the Panigaglia LNG regasification terminal in Italy for Snam S.p.A. From those early years, Saipem was a pioneer in the LNG technology market, patenting several innovative solutions, including the Tealarc™ process developed by Snamprogetti — a precursor of today’s Dual Mixed Refrigerant technology — and the more recent Liqueflex™, compact and efficient, designed for small- and mid-scale applications.

Global leaders across the LNG value chain

Over recent decades, Saipem has made a decisive contribution to the development of the global LNG value chain, designing liquefaction units and regasification terminals worldwide, as well as some of the largest storage tanks ever built. With Moss Maritime, acquired in 2001, it delivered 145 LNG carriers equipped with spherical tanks with high thermal efficiency. This journey has established Saipem as one of the world’s leading players in the sector, active across the entire LNG value chain, both onshore and offshore.

1986 - 1992

A world in transformation

Walls were coming down. The internet was emerging. Barriers of every kind were fading as the world became more connected than ever. And as the digital revolution introduced technologies once unimaginable, Saipem evolved as well: operating in seemingly impossible conditions became just another challenge to overcome.

1987 New strategic alliances

In 1987, Saipem entered a new phase of growth, leveraging joint ventures as a key enabler to access complex markets and strengthen its know-how. Collaborations with partners such as Brown & Root, Clough and Parker Drilling opened up new operational areas, particularly in the North Sea. In a high-risk environment, Saipem also consolidated a new decision-making approach based on rigorous analysis, transparency and trust-building with partners — elements that became essential in addressing new global challenges.

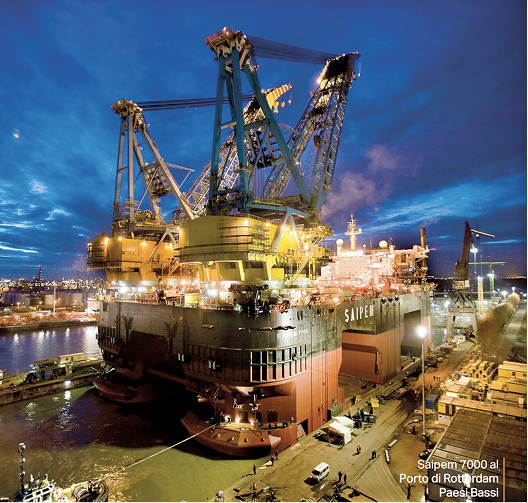

1990 Entry into offshore heavy lifting

In 1990, Saipem made a decisive leap into the offshore heavy lifting sector with the acquisition of the Micoperi fleet, including the legendary Micoperi 7000, later converted into Saipem 7000. This move strengthened the company’s position as a global leader in deepwater and heavy lifting operations, expanding its technical capabilities and taking offshore activities to a new level of complexity and performance.

power, depth and precision

Saipem 7000: power, depth and precision

With its state-of-the-art J-lay tower, a dynamic positioning system upgraded to the highest industry standards, and a rapid ballast system, Saipem 7000 — a semi-submersible crane vessel — is capable of handling the full spectrum of offshore construction activities worldwide. This includes pipeline installation at depths exceeding 2,000 metres and heavy lifting operations of up to 14,000 tonnes.

Insights

Our seabed technologies

Diverless operations and subsea automation

Our seabed technologies: diverless operations and subsea automation

As water depth increases, activities once carried out manually begin to require mechanical equipment. Eyes, hands and arms are replaced by machines that can be remotely operated with precise coordination. Over the years, these systems have become increasingly sophisticated and effective, proving essential especially when rapid intervention is required in emergency conditions.

T.I.E.

System for the recovery of submerged pipelines

The system includes a clamp to grip and lift the pipeline from the seabed, a cutting tool mounted on the frame to cut the pipeline and create an end, and a recovery head. During operation, the recovery head is retrieved from its resting position and inserted into the end of the pipeline, where it locks into place. At this point, the recovery head and the pipeline section are ready to be removed. This invention significantly simplifies the recovery of pipelines from the deep seabed, eliminating the need for diver intervention.

Sonsub

Method for repairing a submerged pipeline

As operational depths increase, pipeline repair can no longer rely on divers and requires fully automated solutions.

The Sonsub method uses ROVs and support frames positioned on the seabed to align the pipeline and make the damaged section accessible. The defective section is cut and removed, while the remaining ends are cleaned using tools designed for deep waters of up to 2,000 metres. A telescopic spool section is then lowered, aligned and expanded to connect the two ends. Final sealing is carried out through a remotely controlled cold forging process, ensuring a rapid, safe and fully diverless operation.

Brutus

Method for connecting subsea pipelines

BRUTUS (“heavy” in Latin) is a high-power integrated connection system designed for large-diameter pipelines. As a basic requirement, the BRUTUS system is lightweight and ROV-compatible (Remotely Operated Vehicle). It is capable of connecting a rigid spool to a rigid pipeline or to an offshore structure and, while being independent of any specific connection system, it minimises the modifications required to subsea hardware.

The BRUTUS system meets the industry’s need to create deepwater connections between rigid pipelines and risers to subsea structures, in any configuration, using spool pieces, flexible elements and standard flanges as preferred connectors, while still allowing the use of other types of mechanical connectors (collets, clamps, etc.).

Hot Tapping

Method and system for securing a support element to a seabed wall

The traditional hot tapping technique is reinterpreted and applied to the recovery of oil from a wreck located at a depth of 3,850 metres. The selected solution involves drilling through deck plates to access the tanks and installing double-shutoff valves. A new hydraulic drill, operated by ROVs, perforates the wreck’s structures to allow the valves to be secured using an anchoring system capable of withstanding extreme hydrostatic forces. The oil, too viscous to be pumped using conventional methods, is released in a controlled manner and collected in special containers before being transported to a refinery.

Petrochemicals

Plants developed from first-generation technologies

Petrochemicals: plants developed from first-generation technologies

Saipem designs and builds petrochemical plants based on a wide range of first-generation technologies, some of which are proprietary and registered under the Snamprogetti brand.

1973 – Process for MTBE production

MTBE, a new high-octane additive developed by the Eni Group in the early 1970s, was introduced into gasoline to replace lead alkyl compounds and improve air quality. In 1973, Snamprogetti built the world’s first MTBE plant in Ravenna using proprietary technology. During the 1980s and 1990s, the product spread rapidly, exceeding 20 million tonnes per year in production and expanding from the fuel sector into the chemical industry, also thanks to its use in producing high-purity isobutylene.

1981 – Decomposition of tert-alkyl ethers (MTBE cracking)

High-purity isobutylene is the monomer used to produce butyl rubber, highly reactive polyisobutylene, methyl methacrylate (MMA) and other derivatives. Cracking MTBE over a suitable catalyst makes it possible to achieve high yields of isobutylene and methanol in a simple way, without issues related to corrosion, toxicity or environmental impact, and with great operational flexibility. This method represents a sustainable alternative to traditional systems for isobutylene production.

1991 – Catalyst prepared using a specific method and its application in a process for producing tertiary olefins from tert-alkyl ethers

The patented catalyst used in the production of high-purity isobutylene ensures very high selectivity and a lifespan up to six times longer than that of competing catalysts.

1993 - 2006

Global expansion

Terrorist attacks. The wars in Iraq and Afghanistan. And an era that, despite the chaos, continued to move relentlessly towards the future. As the world faced unprecedented challenges, a growing digital revolution advanced unstoppable. So did Saipem: building on its international presence, the company embarked on a path towards sustainable development, integrating industry and the environment.

1998 A key player in deepwater pipelaying

By the 1990s, Saipem had become a well-established global player with operations onshore, offshore and in deep waters. In a complex international landscape marked by conflicts, new discoveries and geopolitical change, the company continued to innovate. To address these challenges, Saipem designed the J-lay tower for Saipem 7000, paving the way for extreme offshore projects such as Blue Stream. At the same time, its innovative capability generated a wave of new patented technologies, ranging from submerged pipeline repair to advanced hydrocarbon processes and heavy oil converters, as well as pioneering solutions for LNG liquefaction.

installation really work?

How does J-lay installation really work?

Unlike the S-lay method, J-lay installation keeps the pipeline at a constant angle: the pipe is lifted along a tower connected to the vessel and lowered into the sea without changing its inclination until it reaches the seabed. The name derives from the “J” shape formed by the pipeline. Because the J-lay method subjects the pipe to lower stresses, it can be used at greater depths and in more extreme conditions than the S-lay process.

2001

A new-generation global contractor

In 2001, Saipem acquired Bouygues Offshore. The transaction delivered immediate benefits: Bouygues brought its expertise in civil and marine works into Saipem’s extensive offshore portfolio, while Saipem significantly strengthened its EPCI capabilities on an international scale. The integration of know-how, corporate cultures and operational approaches marked Saipem’s transformation into a global contractor capable of managing complex, multidisciplinary and highly technological projects.

Complex - Argentina (2001)

Bahia Blanca Fertilizer Complex

At the time of its construction, the Profertil project in Bahía Blanca was the world’s largest single-train urea plant, with a capacity of 3,250 tonnes per day. The proprietary urea technology developed by Snamprogetti™ was the first in the world to exceed the threshold of 3,000 tonnes per day, opening up new investment opportunities by leveraging economies of scale with reliable, high-performance solutions.

The plant is located approximately 1 km from the city of Bahía Blanca, a distance that represented a significant challenge during construction.

2006

A global leader in engineering and energy services

With the incorporation of Snamprogetti in 2006, Saipem entered new strategic markets, including downstream and gas liquefaction, expanding its expertise and delivery capabilities. At the same time, the company strengthened its international identity: active in around 70 countries and present in nearly all major oil & gas markets, it boasts a workforce representing more than 125 nationalities. This multicultural dimension expresses Saipem’s true distinctive value: a global company that brings together diverse skills, cultures and visions.

Insights

Pipelaying

Subsea pipeline installation

Pipelaying: subsea pipeline installation

Saipem 7000, one of the largest offshore vessels in the world, enables the installation of large-diameter pipelines at depths exceeding 2,000 metres. Equipped with a 130-metre-high J-lay tower weighing 4,000 tonnes, the vessel operates as a true floating factory: it handles 48-metre-long pipes, prepares their ends and feeds them into the tower through automated systems. Welding, inspection, coating and tensioning operations are fully integrated and centralised. This innovative vertical configuration ensures high reliability, particularly when dealing with irregular seabed slopes in deep waters.

Trenching and backfilling: integrated efficiency for Kashagan

This solution, successfully applied in the Kashagan project, combines a series of coordinated vessels and equipment capable of trenching and backfilling large-diameter pipelines in shallow waters. The system includes a mobile base (such as a barge), a soil crusher operating close to the pipeline, dredging units to remove and transport excavated material, and a backfilling unit to refill the trench. All units are integrated and connected to a control cabin on the mobile base, where software continuously manages excavation and suction parameters, adapting to soils with different characteristics.

Electronic system, method and software for controlling a variable-configuration lay ramp on a pipelay vessel (Castorone)

The most recent addition to the Saipem fleet features a set of innovative solutions: from the unusual position of the firing line, which increases achievable operating depth, to advanced abandonment and recovery systems, along with many other innovations. The patented invention addresses one of the critical phases of pipelaying operations and introduces a variable-configuration lay ramp governed by an electronic control system.

The system collects data on:

- the lay ramp configuration

- the pipelay vessel

- the forces transmitted from the lay ramp and the vessel to the pipeline

It also generates a series of operating sequences to transition from one working configuration to another and selects the optimal sequence to minimise stresses on the pipeline during each intermediate phase between the two configurations.

EST Technology

Bottom of the barrel

EST Technology: Bottom of the barrel

Based on slurry technology, the EST process helps ensure that the maximum possible amount of feedstock is converted into high-value transportation fuels. With competing technologies, 30–40% of the feed volume remains as low-value material. With EST, this figure is reduced to less than 10%.

How EST turns every residue into value

EST — an acronym for Eni Slurry Technology — is an innovative proprietary technology developed through collaboration between Saipem and Eni. It enables the complete conversion of refinery residues, heavy oils and bitumens into light, high-quality products, eliminating the generation of solid and liquid residues (such as coke or fuel oil). The EST process is based on the hydroconversion of heavy feedstocks using a nano-dispersed catalyst (slurry). In refining operations, this technology provides a solution for converting the so-called “bottom of the barrel,” promoting more efficient use of traditional resources — including from an environmental standpoint — and enabling the exploitation of unconventional resources such as extra-heavy crude oil and oil sands.

EST Life Cycle

Early 1990s: CONCEPT & EXPERTISE

Launch of Research & Development activities.

1999–2002: DESIGN & OPERATION

Construction and start-up of the pilot plant.

2002–2005: COMPLETE DESIGN & EPC

Construction of the commercial demo plant.

2005–2008: SITE ASSISTANCE & DESIGN IMPROVEMENT

Start-up and operation of the commercial demo plant.

2008–2013: COMPLETE DESIGN & EPCM

Design and construction of the Sannazzaro industrial unit.

2013–2016: SITE ASSISTANCE & DESIGN IMPROVEMENT

Start-up and operation of the Sannazzaro industrial unit.

2007 - 2017

Corporate transformation

Markets became increasingly complex: oil prices collapsed after years of growth, instability in producing countries intensified, and renewable energy gained momentum. In this context, Eni’s decision to reduce its stake in Saipem accelerated the company’s transformation, opening the door to new opportunities. These changes highlight Saipem’s ability to adapt strategically — an evolution also reflected in the launch of a new brand identity and logo.

2007 - 2010

Navigating global complexity

During these years, Saipem operated in a global context shaped by the financial crisis, sharp fluctuations in oil prices and geopolitical tensions that reshaped the entire energy sector. As the world entered a new phase of globalisation, Saipem demonstrated strong adaptability, strengthening its technical capabilities and maintaining a central role in exploration and production projects in challenging environments. The company also began to embrace digitalisation more fully, anticipating a cultural shift that would shape the years to come.

Kazakhstan (2009)

Kashagan Field Development – Kazakhstan (2009)

The Kashagan field, located in the Northern Caspian Sea, is one of the largest discoveries of the past 30 years.

Its development represented a unique challenge: operations in extremely shallow waters (from 4 to 0 metres), severe environmental conditions and strict access constraints to the area.

Saipem managed all engineering and construction activities — from fabrication to onshore and offshore installation, through to the start-up of Complex ‘D’ and Island ‘A’ — developing innovative solutions and a dedicated fleet for pipelaying and post-trenching operations, including Castoro 12, TRB and Castoro 16.

The EPCI contract, carried out in an isolated area with extremely shallow seabeds and frozen ground, placed strong emphasis on environmental protection. The project included the installation of three 60 km offshore trunklines and approximately 30 km of onshore pipelines, as well as flowlines, umbilicals, and power and fibre-optic cables.

With Kashagan, Saipem set a world record: the longest floating shore pull ever performed — 10 km — for two 28” pipelines and one 18” pipeline.

2011 - 2015

Between new challenges and new opportunities

Between 2011 and 2015, Saipem faced a historical phase marked by significant challenges and transformation. In this context, new gas discoveries in Africa and renewed international commitment to climate issues reshaped industry priorities. Saipem responded with resilience and vision, strengthening its presence in strategic markets and beginning to integrate sustainability and energy transition themes into its strategies. The year 2015 also marked an identity turning point with the renewal of the brand and logo, symbolising a more autonomous, modern and future-oriented Saipem.

Primo Levi’s insight

A curious visit. A wise observation. And a horizon that continues to expand.

When Primo Levi, the renowned Italian writer and scientist, visited Saipem’s Castoro Sei in 1980, he reflected on how it represented the final result of centuries of technological development, tracing back to the very origins of our civilisation.

Speaking about his visit, Levi wrote:

«Just as the automobile incorporated the design of the horse-drawn carriage, Castoro Sei may trace part of its lineage back to pile dwellings and the earliest catamarans. [...] Like the great ideas and profound problems of philosophy… so too the great inventions of technology evolve, but never truly die».

Primo Levi and Paolo Andreocci on board Castoro Sei

2016 - 2017

Sustainability as a driver of growth

During this two-year period, Saipem decisively accelerated its sustainability journey, strengthening its focus on local communities, environmental protection and responsible project management. The company expanded its scope by exploring new activities such as decommissioning, renewable energy, and the emerging wind and solar markets, while digitalisation and innovation became an integral part of its DNA. In this climate of renewal, Saipem also delivered high-value technical achievements, such as the conversion of Scarabeo 9 for the Bosphorus crossing, exemplifying its ability to combine technology, ingenuity and a sustainable vision.

Insights

Drilling:

an innovative approach

Drilling: an innovative approach

A strong focus on innovation is a defining characteristic of Saipem — and the way the company approaches the drilling business is no exception.

From its earliest operations in Sicily, Saipem has consistently invested in innovation in drilling, continuously adopting and developing new solutions to ensure reliable operations in any environment.

The semi-submersible Scarabeo 5, built in 1990, is a clear example: equipped with the most advanced technologies of its time, it operated continuously until 2017, becoming a benchmark for the Norwegian market — one of the most challenging in the world.

Equally iconic is the Saipem 10000 drillship, delivered in 2000, which introduced major innovations such as the dual derrick system. Since then, its design has become a reference model for all new drilling vessels.

Saipem continues to innovate and enhance its solutions, confirming a long-standing tradition of technical excellence. The most recent evidence of the company’s innovative approach is represented by the modifications made to the lifting system (ram system) of the semi-submersible Scarabeo 9.

Designed in 2017, this solution made it possible to carry out the complex crossing of the Bosphorus Strait without the costly dismantling required by traditional units, offering clients a more efficient way to operate in the Black Sea.

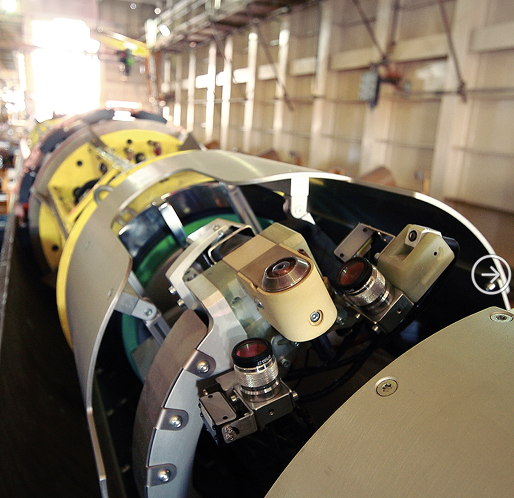

Remotely operated vehicles and robotics

The evolution of Saipem’s subsea robotics

Remotely operated vehicles and robotics

The evolution of Saipem’s subsea robotics

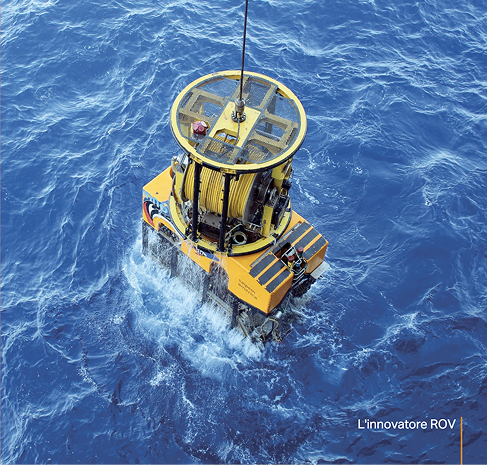

Saipem began designing and manufacturing its own proprietary ROVs following the acquisition of Sonsub in the late 1990s, starting with the first Innovator, which for nearly 20 years was one of the most reliable underwater robots on the market.

The birth of Innovator 2.0: a new subsea robotics standard

In 2015, in response to the oil & gas market’s shift towards increasingly complex projects and sophisticated subsea activities, Saipem initiated the renewal of its ROV fleet with the development of Innovator 2.0. Designed and built in-house, Innovator 2.0 is one of the most powerful and high-performing heavy-work ROVs on the market, capable of operating with umbilicals and tether lengths exceeding 7 km and lifting approximately one tonne thanks to a high-efficiency power system. These features make it suitable for operations in extreme conditions, including very strong marine currents.

By the end of the reference period in 2016, the name chosen for a new type of subsea ROV proved to be forward-looking: the evolution of Saipem’s ROVs was already taking shape through an innovative project set to mark a paradigm shift in subsea operations — the Hydrone platform.

ROVs – Remotely Operated Vehicles

Remotely Operated Vehicles, commonly known as ROVs, are among the most important tools used in deepwater operations, both for collecting information required for the development of offshore fields and subsea pipelines, and for monitoring the integrity of these assets.

Saipem designed its first Innovator ROV in 1999 and has since continued to develop increasingly robust and high-performance ROVs to meet new technological challenges.

Saipem’s investments in Sonsub — the engineering division specialising in autonomous subsea technologies — have transformed the business unit into a global leader in innovation, making Saipem one of the few operators in the market capable of designing, building and managing its own fleet of ROVs, able to operate in extreme conditions: from deepwater environments to hostile scenarios characterised by strong currents, limited visibility or harsh weather conditions.

Welding, Non-Destructive Tracking (NDT), Field Joint Coating

Advanced technologies for pipeline integrity and efficiency.

Welding, Non-Destructive Tracking (NDT), Field Joint Coating

Advanced technologies for pipeline integrity and efficiency.

Automated Ultrasonic Testing (AUT) for CRA/Clad Welds

Clad pipes use lining methods that involve applying an internal layer of corrosion-resistant alloy to an external carbon steel pipe. The two layers are joined through a field weld at the joint root.

The integrity of the weld root area is a critical element. AUT enables a high level of inspection quality across the entire weld and, thanks to dedicated tools, provides enhanced control capabilities to ensure the full integrity of the joint root area.

In addition, an intermediate AUT solution has been developed to allow in-process monitoring of the root area during welding operations. This solution ensures joint integrity throughout the welding phase, delivering state-of-the-art inspection standards while also contributing to improved productivity.

New method using pipe sections welded with internal and external welding

This method involves the combined execution of internal and external welding passes to join pipe sections together. The process requires the creation of a circumferential joint and the execution of an external welding pass, for example using GMAW-MIG (Gas Metal Arc Welding – Metal Inert Gas) torches.

Subsequently, the internal welding pass is performed using a PAW (Plasma Arc Welding) torch, applied to the root pass. This configuration enables a controlled, uniform, and high-quality weld, ensuring joint integrity and overall process reliability.

Proprietary Technologies for Line Joint Quality and Efficiency

SPRINT and SWIPER are proprietary technologies developed by Saipem to enhance the quality, reliability, and productivity of welding and Field Joint Coating processes, ensuring high standards of pipeline integrity and performance.

- SPRINT – Saipem Plasma Remelting Internal Technology

A plasma welding technology that performs controlled remelting of the root pass inside the pipe, ensuring high-quality welds that are free from discontinuities and easily inspectable.

- SWIPER – Wrapping Integrated Polymeric Robotics

A patented technology for the application of Field Joint Coating in a single rotation, delivering speed, reliability, and optimal performance in terms of protection, adhesion, and insulation.

2018 - TOMORROW

One Saipem: clear priorities, tangible results

In the years following its strong commitment to innovation and sustainability, Saipem has progressively defined its role in the future of energy and infrastructure with increasing clarity. From this evolution emerged the One Saipem approach — a shared vision centred on common goals, transparent responsibilities and a concrete focus on results. Within this framework, the latest chapter of the journey takes shape: defining clear priorities to generate sustainable, measurable value.

The strength of a shared vision

Saipem looks to the horizon with curiosity and expertise, anticipating what lies ahead and setting clear priorities to achieve tangible results. Defining objectives means communicating a transparent vision that takes into account the needs, sensitivities and expectations of all stakeholders. This is the core of the One Saipem approach: creating sustainable value. The company operates as a single, integrated organisation, applying and continuously refining its projects with the utmost transparency, while moving towards the Net Zero by 2050 goal, supported by ambitious intermediate targets and a structured sustainability plan.

North Sea (2020)

Seagreen Offshore Wind Farm

The Seagreen 1 offshore wind farm is located in the Outer Firth of Forth, off the east coast of Scotland, 27 km from the Angus coastline. The 1.14 GW project is developed by SSE Renewables and TotalEnergies, in water depths ranging from 42 to 54 metres.

The wind farm comprises 114 wind turbine generators (WTGs) and one offshore substation (OSP). Saipem deployed the heavy-lift vessel Saipem 7000 to install the suction bucket jacket foundations for all 114 turbines, as well as to install the OSP.

Together towards a sustainable future

For Saipem, defining priorities is not enough: it is essential to report results in a clear and verifiable way. For this reason, the company presents its strategies, programmes and performance every year in its Sustainability Report — a tool that has positioned Saipem among sustainability pioneers since 2006. Measuring the real impact of its work and sharing it transparently enables continuous improvement, adaptation to change and the amplification of positive outcomes. This is how Saipem is building a sustainable future. Today. Together.

Insights

Robotics:

the new frontier of subsea robotics

Robotics: the new frontier of subsea robotics

Since 2016, Saipem has been leading a decisive evolution in subsea robotics through the Hydrone Platform — a modular and innovative solution that is redefining how subsea activities are managed, enhancing safety, operational continuity and sustainability in offshore operations.

The Hydrone Platform is a modular system composed of three vehicles designed to operate without a support vessel, ensuring high flexibility and a significant reduction in costs.

FlatFish (Hydrone-S) is an advanced autonomous drone capable of carrying out complex deepwater surveys, by tracking risers and pipelines and operating in close proximity to subsea structures.

Hydrone-R combines ROV and AUV functionalities in a hybrid system that enables tetherless interventions in subsea fields, either remaining permanently subsea or being managed from the surface for advanced inspection activities.

Hydrone-W, finally, is a fully electric Work Class ROV, designed to operate more sustainably thanks to a high-efficiency powertrain.

Together, they form a new family of “underwater drones” with hybrid ROV/AUV capabilities, operable both offshore and from onshore Control Rooms via satellite and acoustic/optical links.

The Hydrone Platform delivers significant advantages in the management of subsea operations. It ensures operational continuity even in complex or remote fields, while reducing risk and environmental impact through a substantial decrease in CO₂ emissions related to IMR activities and the reduced need for support vessels.

It also contributes to cost reduction in EPCI projects, simplifying preparatory operations such as surveys, metrology and equipment handling.

Saipem’s continuous investment led to the award of the first-ever “drone service” contract in the industry, with the supply of Hydrone-R to Equinor in 2019. The ultimate goal of the programme is to increase safety, efficiency and digitalisation of subsea activities, enabling a new generation of offshore interventions focused on the sustainability of both brownfield and greenfield projects.

Carbon Capture, Utilisation and Storage (CCUS)

Low-carbon technologies for the energy transition

Carbon Capture, Utilisation and Storage (CCUS)

Low-carbon technologies for the energy transition

Saipem is a global leader in engineering and technologies, leveraging the expertise of its people to diversify its sustainable offering and act as an enabler of the energy transition, unlocking untapped energy resources through its low-carbon solutions.

The company’s product lines range from carbon-free solutions — such as offshore wind and green hydrogen (and its derivatives) — to low-carbon solutions like CCUS, which transform conventional oil & gas assets into a carbon-neutral approach, applicable to both greenfield projects and brownfield contexts.

CARBON CAPTURE – CO₂ capture

Saipem has designed and delivered more than 70 CO₂ removal plants, using a wide range of technologies — from membranes to physical and chemical solvents. The company also offers an advanced post-combustion CO₂ capture technology.

RE-USE PLANTS – Utilisation facilities

Saipem designed and built the world’s largest methanol plant (at the time of construction), capable on its own of reducing 360,000 tonnes of CO₂ per day. Globally, 136 plants have been delivered — more than 40 engineered and built by Saipem — converting CO₂ into urea through the proprietary Snamprogetti™ Urea technology.

CO₂ TRANSPORTATION

With over 130,000 km of pipelines and sealines engineered and installed in challenging and remote areas, Saipem ranks among the world leaders in the sector, supported by its offshore fleet.

STORAGE

- More than 7,000 onshore and offshore wells drilled onshore and offshore

- Acid gas reinjection technologies for CO₂ sequestration

- A recent example is the Cornegliano Laudense CO₂ storage facility