With a long track record in the Engineering and Construction of offshore energy infrastructure, Saipem is keenly focused on the Offshore Wind market, with operations concentrated on contributing to the energy transition, with a commitment to the path of a sustainable future.

From early engagement through construction and operations, we offer our services to developers of Offshore Wind, across the full development life cycle.

Fixed-bottom solutions

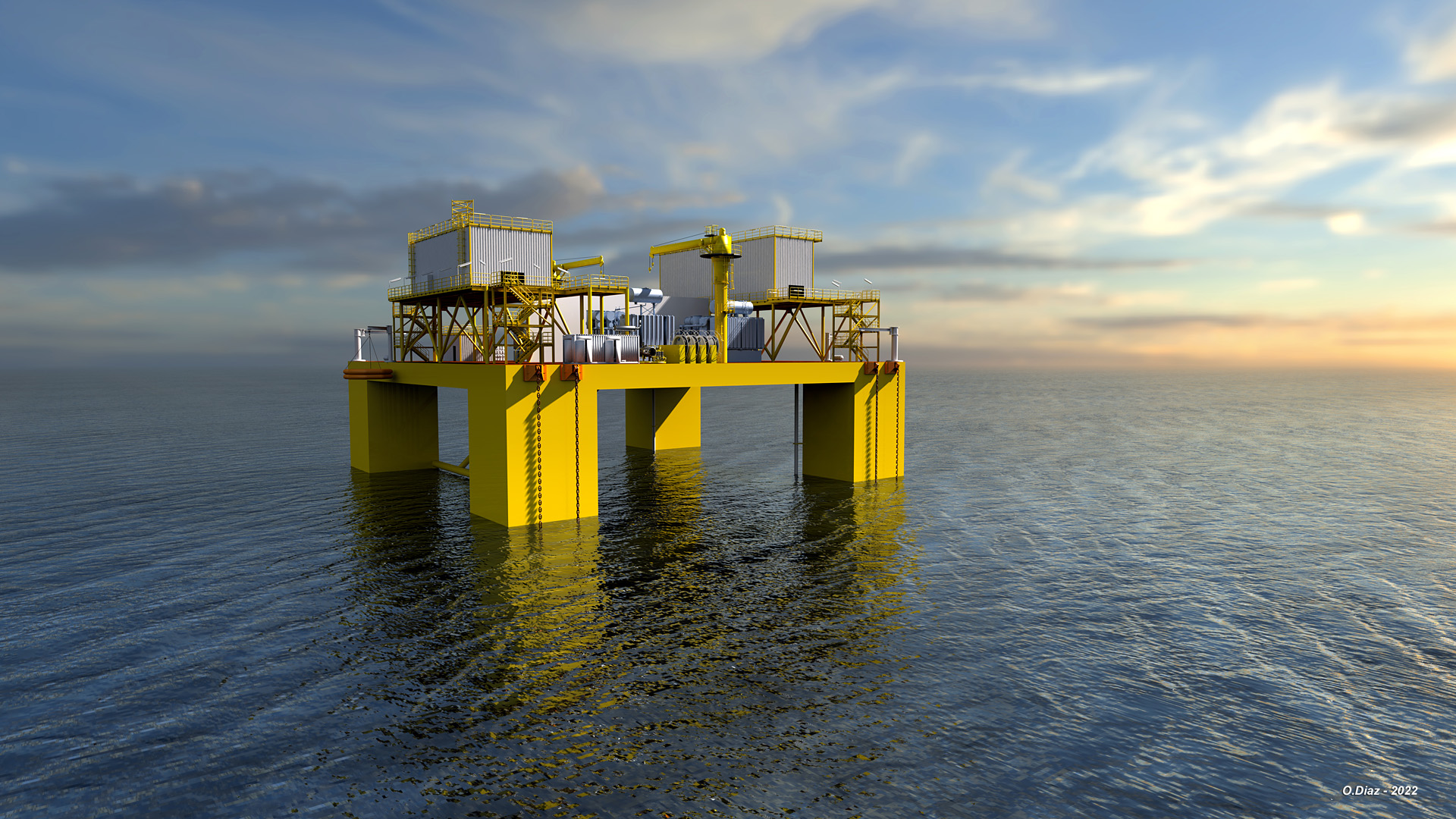

Saipem is uniquely positioned to offer full-EPCI of foundations, for both Wind Turbine Generator Jacket Foundations and Offshore Substations, leveraging in-house capability for engineering and fabrication in Arbatax (Italy) and Karimun (Indonesia).

Arbatax in Sardinia is ideally positioned to support Europe and the United States with the EPC of HVAC Offshore Substations, both Jacket and Topside structures, with the Saipem S7000 enabling the installation of this critical infrastructure.

The extensive area of the Karimun yard is well suited to serial jacket foundation production, having developed a strong track record of fabrication and delivery of these structures to Europe and the Far East. Karimun may also be considered for the construction of larger HVAC Offshore Substations and, as developments move further offshore, future HVDC units.

Owning and operating the Saipem S7000 Heavy Lift Vessel; a semi-submersible with 14,000Te dual crane lift capacity, Saipem is prepared and equipped to support Offshore Wind Developers with the installation of the next generation of XXXL Wind Turbine Generator foundations. Our continuous commitment to providing innovative solutions, upgrading and maintaining our assets and equipment to meet the evolving challenges of the market, brings confidence and development certainty to our clients.

We are proud of our unique EPCI track record of undertaking Monopile, Gravity Base Structure (GBS) and Jacket foundation contracts, in the key European offshore market, and are transferring these skills to enter growth markets in regions such as the USA and further afield.

The EPCI of the Fécamp Offshore Wind Gravity Base Structure foundations is one of our successes. Off the Normandy coast of Fécamp, in north-west France, stands a 500 MW Offshore Wind field. The 71 wind turbines have been successfully constructed and installed off the coast of Fécamp.

In collaboration with Bouygues Travaux Publics and Boskalis, we have completed the engineering, procurement, construction, and installation offshore of these foundations.

Crossed by strong, regular winds; the Fécamp wind park will produce the equivalent of the domestic energy consumption of approximately 770,000 people. The project partners are EDF Renewables and Enbridge, who hold 35% each through Éolien Maritime France, with wpd Offshore holding the remaining 30%.

With each GBS weighing up to 5,000Te and standing 48 to 54 metres tall, the GBSs provide stability to the 7 MW wind turbine generators, fixed on top. Boskalis designed the gravel pad seabed preparation, ahead of the GBS installation works, completing the solid ballasting and scour protection, once the foundations were successfully in position.

The achievement of this major goal to develop the Offshore Wind site in Fécamp is proof of the prospects of growth within the Offshore Wind market, focusing on a commercial and executive strategy of EPCI contracts for fixed-bottom installations, which will also follow through into the upcoming Floating Wind segment.

Further up the North Sea, in the UK sector, two further significant offshore wind farms have been completed by Saipem in the form of the Neart na Gaoithe Project and the Seagreen 1 Project, which were both completed in 2023.

Floating wind solutions

Floating Wind technologies will be at the forefront of a zero-carbon emission future, heading into the next decade. Saipem provides not only Fixed-Bottom Offshore Wind solutions, assets and expertise, but also proprietary technology for Floating Wind WTG foundations and Floating-Offshore Substations, enabling clients to realize their developments.

In all our technologies related to Floating Wind, be it Floating Foundations or Substations, Saipem utilises its expertise and know-how, as an experienced EPCI contractor and fabricator, so that our concepts are intrinsically conceived considering fabricability, installability, operability and maintainability. Saipem’s products can be easily industrialized and, for floating foundations, we have developed an efficient serial production method.

Amongst our floating foundations solutions, STAR1 represents a very mature semi-sub design, being commercialized on several projects around the world through the studies we are carrying out for our clients. The STAR1 design is characterised by a centred turbine that optimizes the global behaviour of the foundation, providing a very high stability in harsh conditions, a best-in class weight and a very low draft to improve accessibility in the majority of ports, while performing the Wind Turbine integration. The design has proven to be very scalable for turbines beyond 15 MW in size. Endowed with a passive ballast system, the concept provides for high reliability and ease of maintenance.

The manufacturing process is based on building blocks, columns, and pontoons, that can be easily fabricated in the shipyards, and then finally assembled at locations near the windfarms’ final locations. For final assembly, Saipem has developed its Smart Yard concept, an assembly process that requires very limited space at quayside, has a very limited number of connections between “megablocks” and utilizes automated welding and NDT technologies, without the need of handling or assembling any elements at height.